| Home | Products | Discover Tovasty | Production Process | Tech | Contact Us |

|

The Friction Materials Standards Institute (FMSI) is a trade association of automotive aftermarket friction manufacturers that created a standardized part numbering system for brakes and clutch facings for all on-highway vehicles in use in North American. Its main responsibilities are the development, maintenance, and promulgation of a standardized part numbering system for brake friction for its members and their customers. Thus, the manufacturing members and their customers both have the right to use this system. From manufacturer through retailer/installer, one part number is used as the standard and as a common language - the FMSI number. Membership in the FMSI is open to any manufacturer of friction and related products covered by the trademarked FMSI and FMS part numbers.

Both FMSI and FMS are registered trademarks of the Friction Materials Standards Institute. (Source: FMSI webstie)

The Automotive Manufacturers Equipment Compliance Agency, Inc. (AMECA) was incorporated in late 1994 to continue providing the same safety equipment services to the states that the American Association of Motor Vehicle Administrators, (AAMVA) had provided since 1967.

As with AAMVA, AMECA has individual signed agreements with various states for providing equipment compliance services as their agent. This is the same arrangement that AAMVA had until the discontinuation of their Safety Equipment Services (SES) on 31 December 1994. The AMECA program is a centralized on-stop program that notifies government, industry and the general public about items of motor vehicle safety equipment that have been tested by an AMECA-accredited laboratory and found to be in complicance with applicable United States standards. Our clients and market are the national and international automotive industry, the standards-setting community, the federal government's General Services Administration (GSA), numerous state governments, as well as some foreign governments.

AMECA maintains a listing of items that have been tested and currently comply with the applicable standards. Called the "Compliance List of Automotive Safety Devices", this listing is updated quarterly and is available as an Adobe PDF document distributed via email. The international "list of Acceptable Plastics for Optical Lenses and Reflectors Used on Motor Vehicles" is also maintained by AMECA. This document is updated twice a year is also available as an Adobe PDF document distributed via email. To receive your free copy of the either document send an email request to info@ameca.org.

All items submitted through the AMECA program must be properly marked and identified. Each item is completely re-traceable to the manufacturer, to the testing laboratory and to the raw test data retained by the testing laboratory.

Our laboratory accreditation program invites both independent laboratories and industry laboratories to apply for our accreditation. We have had excellent success with this program. In the 32 years of the program, we have never had difficulty with our accredited laboratories.

All 66 currently accredited laboratories have complied with the AMECA written criteria and have been audited on-site by AMECA on a periodic basis. AMECA maintains close and regular communication with its accredited laboratories as well as with local, state and federal governments.

Many state laws regulating automotive safety equipment were promulgated by the Vehicle Equipment Safety Commission (VESC) of the Vehicle Equipment Safety interstate compact. VESC regulations continue to be used by the states. AMECA maintains a complete list of VESC regulations that pertain to motor vehicle safety components and has recently obtained all historical documents pertaning to the VESC.

AMECA staff members voluntarily participate on various consensus standards committees such as Society of Automotive Engineers (SAE) committees on lighting, brakes, emergency lighting and sirens, and the American National Standards Institute, (ANSI) Z26.1 committee on glazing materials. The AMECA Program is financed exclusively by fees received for processing submissions, laboratory audit charges and from listing fees and publications. We receive no funding from the states we represent, nor any government or contribution funds from the government or the general public.

Each day we receive communications from every corner of the world with questions we try to answer in order to help industry and governments carry out their needs and responsibilities.

Automotive Quality Management System

ISO/TS 16949 will secure your reputation in global markets

--------------------------------------------------------------------------------------------------------------

ISO/TS 16949 is designed to help companies to implement effective and robust Quality Management Systems relating to the design, development, production, installation and servicing of all automotive related products.

ISO/TS 16949 offers the following benefits:

* Improves product and process quality, reducing overheads, waste and error

* Increases on-time delivery

* Ensures absolute consistency throughout the supply chain

* Satisfies automotive mandates of International Automotive Task Force (IATF) members around the world

* Eliminates the need for compliance to multiple third party registrations in different countries

* Increase competitiveness in global markets

* Meet demand for the direct provision of substantiating information

ISO 14001:2004 sets out the criteria for an environmental management system and can be certified to. It does not state requirements for environmental performance, but maps out a framework that a company or organization can follow to set up an effective environmental management system. It can be used by any organization regardless of its activity or sector. Using ISO 14001:2004 can provide assurance to company management and employees as well as external stakeholders that environmental impact is being measured and improved.

The benefits of using ISO 14001:2004 can include:

* Reduced cost of waste management

* Savings in consumption of energy and materials

* Lower distribution costs

* Improved corporate image among regulators, customers and the public

There are no regulatory standards for replacement brake pads in North America!

This means that there are no minimum requirements for either product performance or product content in these components. International manufacturers working with domestic distributors import brake pads from questionable sources with questionable content. Typically, brake pads readily available in our markets that were manufactured offshore still contain asbestos, which has been proven to be harmful to human health.

In the United States, things are slowly changing. The government is in the process of banning the use of copper in friction materials because it has been proven that copper is extremely toxic to fish. In August 2010, California passed legislation that mandates the elimination of copper in motor vehicle brake pads by 2025

Make sure you ask about the origins of your replacement brake pads! If you don't, you will be assuming that the available replacement parts are safe, and you will not know for sure if the parts suppliers have chosen to sacrifice your safety in their quest to maximize profits.

|

Contains more than 5% of Copper by weight (a) Asbestiform fibers, less than 0.1% by weight (b) Cadmium and its compounds, less than 0.01% by weight (c) Chromium (VI)-salts, less than 0.1% by weight (d) Lead and its compounds, less than 0.1% by weight (e) Mercury and its compounds, less than 0.1% by weight |

|

Contains between 0.5% and 5% of Copper by weight (a) Asbestiform fibers, less than 0.1% by weight (b) Cadmium and its compounds, less than 0.01% by weight (c) Chromium (VI)-salts, less than 0.1% by weight (d) Lead and its compounds, less than 0.1% by weight (e) Mercury and its compounds, less than 0.1% by weight |

|

Contains less than 0.5% of Copper by weight a) Asbestiform fibers, less than 0.1% by weight (b) Cadmium and its compounds, less than 0.01% by weight (c) Chromium (VI)-salts, less than 0.1% by weight (d) Lead and its compounds, less than 0.1% by weight (e) Mercury and its compounds, less than 0.1% by weight |

| Washington State legislation requires all brake pads and shoes manufactured after January 1, 2015 are required to have a Leafmark icon indicating the level of compliance with state friction material content legislation. |

The primary cause of brake system noise is vibration and all brake systems vibrate to one degree or another creating an initial noise. For the most part this initial noise is beyond detection to the human ear. In part this is due to the dampening effect which the larger mass brake components generate in the system. The key factor in dampening initial noise is the stability or rigidity of the brake system components. In most O.E. disc brake designs, dampening is assisted by (1) insulators called shims or noise suppression gaskets which reduce vibration between the disc rotor plate and the caliper brake pad contact surfaces and/or (2) guide plates or abutment clips and the caliper mounting brackets assure rigidity of those components.

When the initial noise in the brake system is amplified (instead of dampened) to a level which becomes disagreeable to the vehicle operator, this amplification is called a secondary vibration. The secondary vibration occurs when the initial vibration frequency reaches an audible level with a high enough frequency for the driver to hear and be concerned.

Friction materials are not normally the cause of a secondary vibration. It generally results from rust, distorted or loose components and/or the wearing or weakening of an original part. As components weaken or become fatigued from the heat and stress generated in the brake system, they no longer fit as tightly as necessary to maintain proper rigidity. Any vibration resulting from the pad backing plate to caliper contact points will result in a very audible, irritating noise such as squeal.

Many technicians believe that changing to disc pads with a “softer” (more forgiving) friction material will cure noise problems. In reality, changing to the “softer” material changes the balance of the brake system, and this results in a change in noise frequency to an inaudible noise level. The important tradeoff to consider; wear rate of softer pads is much higher, life expectancy is greatly reduced. Thermodynamics may be altered affecting brake safety and efficiency.

Understand vehicle brake balance:

With 70%-85% or more of the braking performed by the front disc brakes while 15%-30% is done by the rear brakes.

Older rear wheel drive vehicles performed 55%-60% of braking up front and 40%-45% in the rear brakes.

Front wheel drive disc operating temperatures are much higher, resulting in increased glazing and wear.

Any brake system is capable of generating noise. While braking under these extreme conditions heat build up causes glazing of the friction surfaces (a thin surface hardening or flaking is formed on the surface of pads/shoes) and all these conditions can produce noise.

Brake noise may be heard during light brake applications, and usually when the brakes are cold. Make sure caliper and pads move freely and are lubricated. Make sure the guides or slides are not making contact with the rotor. Remove and sand friction on a flat surface and reinstall.

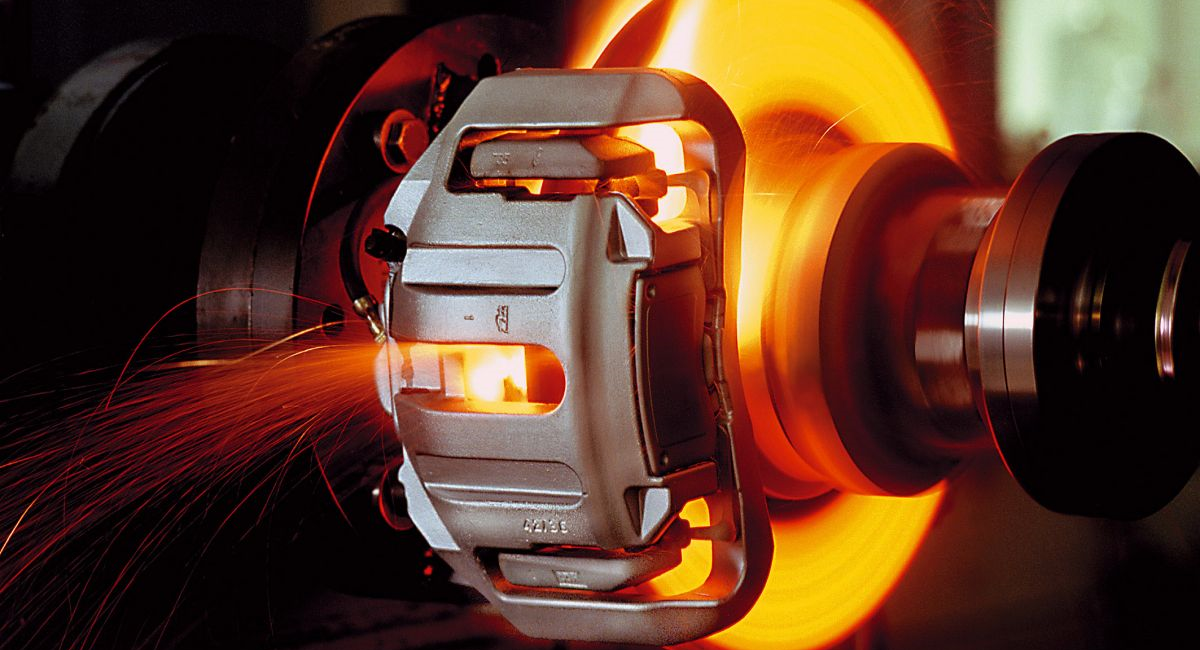

Repeated braking in heavy traffic or hilly driving conditions. During these very demanding operating conditions temperatures can reach 1000 degrees or more. At these temperatures brake squeal is a common occurrence due to a metallurgical structure change that occurs in the rotor or drum surface.

A dynamometer ("dyno") allows testing of friction materials (brake) in an in-jouse environment as an alternative to conducting vehicle testing. Inertia dynamometer testing, approved by vehicle and axle manufacturers and government authorities, simulates vehicle-driving conditions, thus producing results more quickly than road testing.

In the United States, the Department of Transportation issues a Federal Motor Vehicle Safety Standard (FMVSS), which involves dyno testing that test few performance aspects. An effectiveness test measures the efficiency of the brake and different pressures, the fade test indicates brake performance (or failure) at a high deceleration (high temperature) rate, and a recovery test is performed at a lower deceleration rate.

Asbestos or chrysotile asbestos was used for decades in the manufacture of automotive brakes and brake linings. It provided excellent heat and friction resistance, durability, and was inexpensive.

Even though asbestos has been banned for many commercial uses since the late 1970s, the Environmental Protection Agency (EPA) allows its use in materials in which the asbestos fibers are tightly bound, including disc brake pads, drum brake linings, and brake blocks. Asbestos linings and brakes are widely available in the aftermarket and are still used in high-end luxury cars.

When the asbestos fibers remain firmly bound in material, there is no danger; however, if the material is damaged or worn in any way, microscopic asbestos fibers can be released into the air. When you breathe them in, the fibers can become lodged in the lungs and, after many years, can cause serous diseases such as asbestosis (scarring of the lungs) and several forms of lung cancer, including mesothelioma.

|

| © 2016 TJH Group. All rights reserved. |